THC – torch height controller – is device, that enables the most precise cuts on CNC plasma cutter with automatic torch height control. The main feature is that it enables automatic adjustment between torch and material and that compensates the curvature in material. That way the cutter is always the same distance from the material and cuts are clean and precise. It does that by measuring and monitoring arc voltage and by compensting it ensures your torch or cutting head doesn’t get too close or far from the workpiece.

THC – torch height control solves the problem of warped metal sheets. Warped sheets cause the distance, between the part and the torch to vary which leads to uneven and ugly cuts if we cut it without THC. THC with CNC Plasma floating head enables to adjust and maintain the distance between the workpiece and the torch so the cuts are precise and crisp.

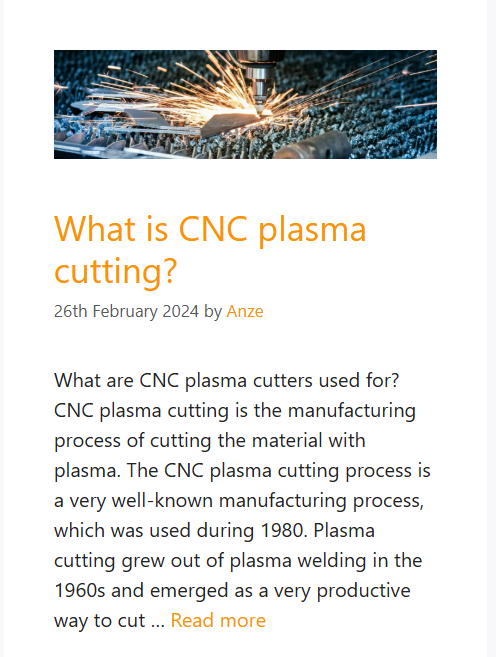

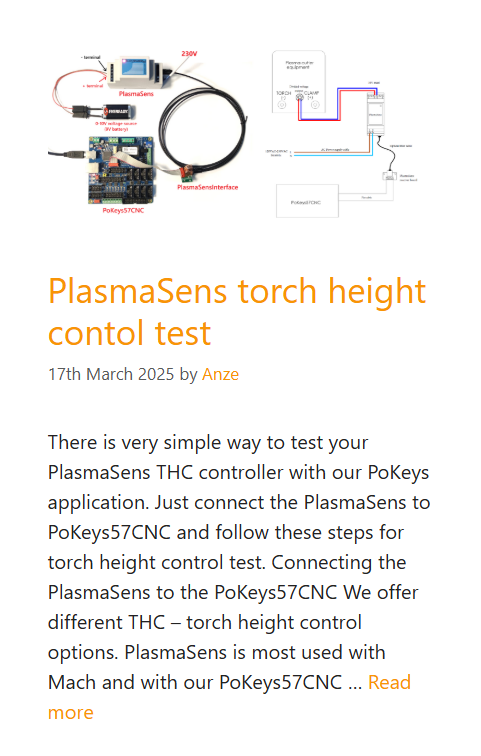

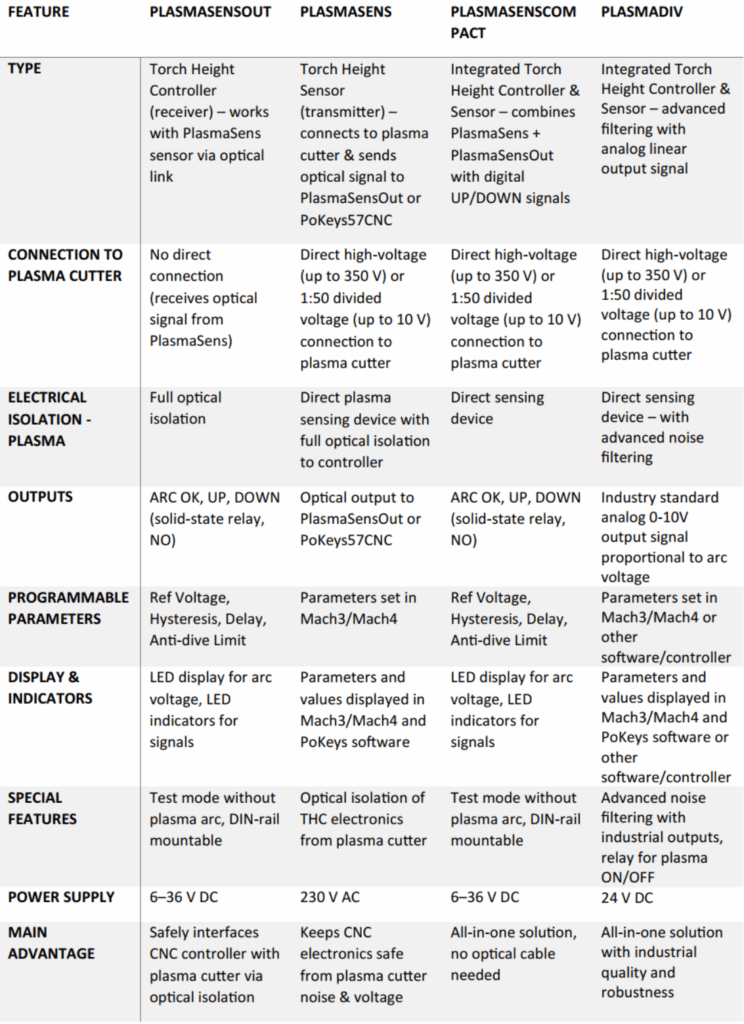

We offer PlasmaSensOut that has digital output signals for up, down and ok. PlasmaSensCompact has the same functionality as PlasmaSensOut but with compact enclsoure that packs both plasma voltage detector and digital up, down and ok output signals. PlasmaSens with PlasmaSensInterface enables the PoKeys device to directly read the real time height of the torch and adjust the height in the software with torch height control. PlasmaDiv on the other hand is the newest product that has state of the art filtering and enables direct connection to the plasma arc voltage and has isolated output that can be fed directly into PoKeys for reading 0-10 V torch height. It also incorporates the relay for plasma on/off command.

Recommended products

-

Plasma voltage divider – PlasmaDiv

199,00 € excl. VAT & Shipping -

PlasmaSensInterface – PlasmaSens receiver

19,90 € excl. VAT & Shipping -

PlasmaSensOut – torch height controller

159,90 € excl. VAT & Shipping -

PlasmaSens – Torch Height Controller for CNC plasma

89,90 € excl. VAT & Shipping -

PlasmaSensCompact – torch height controller

148,90 € excl. VAT & Shipping

The main difference between manual, automatic, and arc voltage torch height control (THC) is in how each system maintains the correct distance between the plasma torch and the workpiece during cutting. In a manual THC setup, the operator must adjust the torch height by hand before and even during cutting, relying on visual judgment and experience. This method is simple but often lead to inconsistent cut quality, especially on warped or uneven material. Automatic THC systems, on the other hand, use sensors or feedback mechanisms to control the torch height without operator input, ensuring consistent standoff distance throughout the cut. The most common type of automatic system is arc voltage THC, which monitors the plasma arc voltage in real time — since arc voltage directly correlates with torch-to-work distance, the controller automatically raises or lowers the torch to maintain a preset voltage. This allows for smoother, more accurate cutting, longer consumable life, and improved performance on materials with surface irregularities.

The Torch Height Control (THC) system determines the correct torch height by monitoring the arc voltage between the plasma torch and the workpiece during cutting. This arc voltage is directly proportional to the distance between the torch tip and the metal surface — as the torch moves farther away, the voltage increases, and as it gets closer, the voltage decreases. The THC is programmed with a target or setpoint voltage that corresponds to the optimal cutting height specified by the plasma cutter manufacturer. During the cutting process, the THC continuously compares the real-time arc voltage to this setpoint and automatically adjusts the Z-axis up or down to maintain the correct standoff distance. This ensures consistent cut quality, proper penetration, and extended consumable life, even when the material surface is uneven or warped.